Let Us Call You Back or Check Our Address

Let Us Call You Back or Check Our Address

The prices you see here are linked to foreign exchange rates and will be adjusted on a weekly/bi-weekly basis. However, during the quotation valid period, the price we quoted for you will be fixed and valid until the quotation expires. If you haven't paid as yet, a new quotation will be created and new pricing will apply.

The prices you see here are linked to foreign exchange rates and will be adjusted on a weekly/bi-weekly basis. However, during the quotation valid period, the price we quoted for you will be fixed and valid until the quotation expires. If you haven't paid as yet, a new quotation will be created and new pricing will apply.

We provide bounded attribute guarantee on the entire machine, including any subsystem unless stated differently. Poor craftsmanship along with defective material errors are covered by the attribute guarantee. We are not at fault for general wear and tear or mis-usage of your component. Our guarantee will accordingly not cover aforesaid. Of course, damages that are not covered under warranty can often be repaired at a minimal cost. Quotations will be gladly accessible upon demand.

We provide bounded attribute guarantee on the entire machine, including any subsystem unless stated differently. Poor craftsmanship along with defective material errors are covered by the attribute guarantee. We are not at fault for general wear and tear or mis-usage of your component. Our guarantee will accordingly not cover aforesaid. Of course, damages that are not covered under warranty can often be repaired at a minimal cost. Quotations will be gladly accessible upon demand. Our warehouse offers basic and/or full training courses for all machinery we sell. When obtaining your machinery, first basic entry courses is combined in your purchase, but more advanced training can be bought after the basic course has been completed.

Our warehouse offers basic and/or full training courses for all machinery we sell. When obtaining your machinery, first basic entry courses is combined in your purchase, but more advanced training can be bought after the basic course has been completed. Whenever a specialist supplies a service at your place, it points to to a call-out. Except when the call-out is included by any of the above mentioned plans or per-approved by the the company, a call-out fee will be requested. At the extent of this quotation, 1 technician for one day is R 1 499.00 for weekdays, R 4 995.00 for Saturdays including R 9 995.00 for resting days or Public Holidays.Along with the call-out charge, touring costs to your premises including accommodation if required, are on your account. The specialists required preparations to be done to get picked up and sent back, are chosen to be carried out by you. If you would prefer for us to come to you, the current amount is R 9.95/km multiplied by the driving distance between our warehouse and your place.Kindly analyze about call out including transport costs in advance as those charges may vary point by instant without notice.

Whenever a specialist supplies a service at your place, it points to to a call-out. Except when the call-out is included by any of the above mentioned plans or per-approved by the the company, a call-out fee will be requested. At the extent of this quotation, 1 technician for one day is R 1 499.00 for weekdays, R 4 995.00 for Saturdays including R 9 995.00 for resting days or Public Holidays.Along with the call-out charge, touring costs to your premises including accommodation if required, are on your account. The specialists required preparations to be done to get picked up and sent back, are chosen to be carried out by you. If you would prefer for us to come to you, the current amount is R 9.95/km multiplied by the driving distance between our warehouse and your place.Kindly analyze about call out including transport costs in advance as those charges may vary point by instant without notice. Without going away from our place, we are able to connect to your CPU to help you with the configuration and technical difficulties right away with Broadband internet and promoted programming automation. When relating to diagnosis on all machinery we sell that associates to and functions with a PC, as well as the fitments and organization on all software we sell, we present lifetime unlimited remote help. Remote assistance is not comparable to training.

Without going away from our place, we are able to connect to your CPU to help you with the configuration and technical difficulties right away with Broadband internet and promoted programming automation. When relating to diagnosis on all machinery we sell that associates to and functions with a PC, as well as the fitments and organization on all software we sell, we present lifetime unlimited remote help. Remote assistance is not comparable to training. All our mainline of machines are sold with a different barcode. You will thus constantly be able to check the machinery's assurance data and assistance history on our webpage or while disconnected - in any manner and at any time. By using the barcode we honour our machines guarantee and assistance. Maximum advantage are ensured on both the selling and servicing of your machinery's.

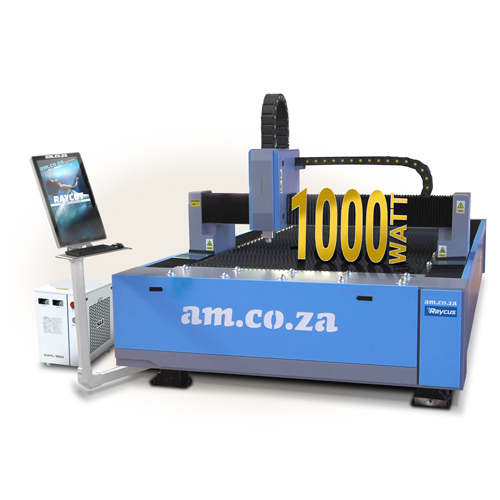

All our mainline of machines are sold with a different barcode. You will thus constantly be able to check the machinery's assurance data and assistance history on our webpage or while disconnected - in any manner and at any time. By using the barcode we honour our machines guarantee and assistance. Maximum advantage are ensured on both the selling and servicing of your machinery's. Seeing that the reference above is in regarding to our advanced model, the climax, details and attachments are relevant thereto. Generously analyze from our sales clerk as to the age model cited. You will be entitled to collect a 5% discount on prior models , depending on lower execution or lesser design in which case we do not have the brand new model accessible.

Seeing that the reference above is in regarding to our advanced model, the climax, details and attachments are relevant thereto. Generously analyze from our sales clerk as to the age model cited. You will be entitled to collect a 5% discount on prior models , depending on lower execution or lesser design in which case we do not have the brand new model accessible.