Let Us Call You Back or Check Our Address

Let Us Call You Back or Check Our Address

We offer confined characteristic guarantee on the whole machine, and each subsystem unless stated otherwise. The quality warranty covers defects by reason of defective components or poor craftsmanship We would not be held responsible for misuse or general wear and tear of your machine. Aforementioned is therefore not covered by our warranty. Damages can usually be repaired that aren't covered under guarantee, at minimum cost. Quotations are readily available on inquiry.

We offer confined characteristic guarantee on the whole machine, and each subsystem unless stated otherwise. The quality warranty covers defects by reason of defective components or poor craftsmanship We would not be held responsible for misuse or general wear and tear of your machine. Aforementioned is therefore not covered by our warranty. Damages can usually be repaired that aren't covered under guarantee, at minimum cost. Quotations are readily available on inquiry. Our training centre offers primary and/or overall training courses for all machines we sell. First fundamental entry courses is enclosed in your machinery investment, however more advanced training can be obtained after the basic course has been accomplished.

Our training centre offers primary and/or overall training courses for all machines we sell. First fundamental entry courses is enclosed in your machinery investment, however more advanced training can be obtained after the basic course has been accomplished. Every time a technician supplies a service at your property, it refers to a call-out. Except for when confirmed by management or concealed by any of the above mentioned plans, a call-out fee will be charged. 1 specialist for one day is R 1 499.00 for weekdays, Traveling for weekends as well as R 9 995.00 for Sundays or Public Holidays at the instant of this quotation. costs to your establishment as well as accommodation if necessary, are on your account, along with the call-out fee. We choose that you organize that the technician gets picked up as well as sent back. R 9.95/km is the prevailing amount increased by the driving distance between your property including our place, should you desire for us to come to you.Attentively seek an answer about call out as well as traveling costs in advance as those charges may change extent by instant without notice.

Every time a technician supplies a service at your property, it refers to a call-out. Except for when confirmed by management or concealed by any of the above mentioned plans, a call-out fee will be charged. 1 specialist for one day is R 1 499.00 for weekdays, Traveling for weekends as well as R 9 995.00 for Sundays or Public Holidays at the instant of this quotation. costs to your establishment as well as accommodation if necessary, are on your account, along with the call-out fee. We choose that you organize that the technician gets picked up as well as sent back. R 9.95/km is the prevailing amount increased by the driving distance between your property including our place, should you desire for us to come to you.Attentively seek an answer about call out as well as traveling costs in advance as those charges may change extent by instant without notice. Without leaving our warehouse, we are able to connect to your PC to assistance you with the setup and technical difficulties directly with large bandwidth cyberspace and advanced programming automation. We supply endless unlimited remote help for fitments and organization on all the software, as well as for investigation on all machines we sell that joins to and works with a computer. Remote service is not the same to training.

Without leaving our warehouse, we are able to connect to your PC to assistance you with the setup and technical difficulties directly with large bandwidth cyberspace and advanced programming automation. We supply endless unlimited remote help for fitments and organization on all the software, as well as for investigation on all machines we sell that joins to and works with a computer. Remote service is not the same to training. A individual barcode is presented with all our mainline of machines. Thus your machines assurance information and assistance history will always be able to be analyzed in any manner and at any time on our database or while logged off. By using the barcode we value our machines assurance and maintenance. Ultimate comfort are protected on both the selling and assistance of your machinery's.

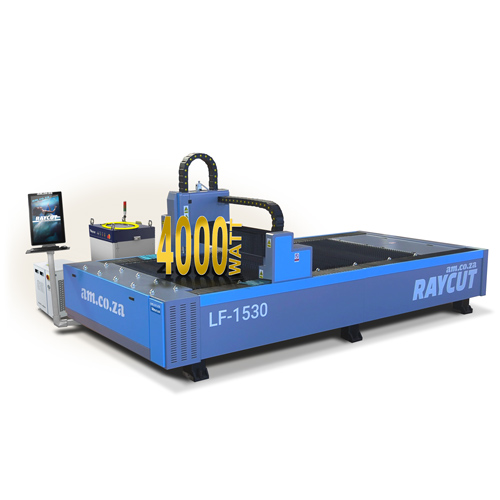

A individual barcode is presented with all our mainline of machines. Thus your machines assurance information and assistance history will always be able to be analyzed in any manner and at any time on our database or while logged off. By using the barcode we value our machines assurance and maintenance. Ultimate comfort are protected on both the selling and assistance of your machinery's. The reference above involves our brand new model, and in essence the climax, specifications as well as extras are relevant thereto. Our Sales clerks can be called in regarding to any questions of the age model recited. Depending on lower achievement or insignificant layout, you will be titled to collect a 5% exemption on former models, in which case we don't have the brand new model vacant.

The reference above involves our brand new model, and in essence the climax, specifications as well as extras are relevant thereto. Our Sales clerks can be called in regarding to any questions of the age model recited. Depending on lower achievement or insignificant layout, you will be titled to collect a 5% exemption on former models, in which case we don't have the brand new model vacant.